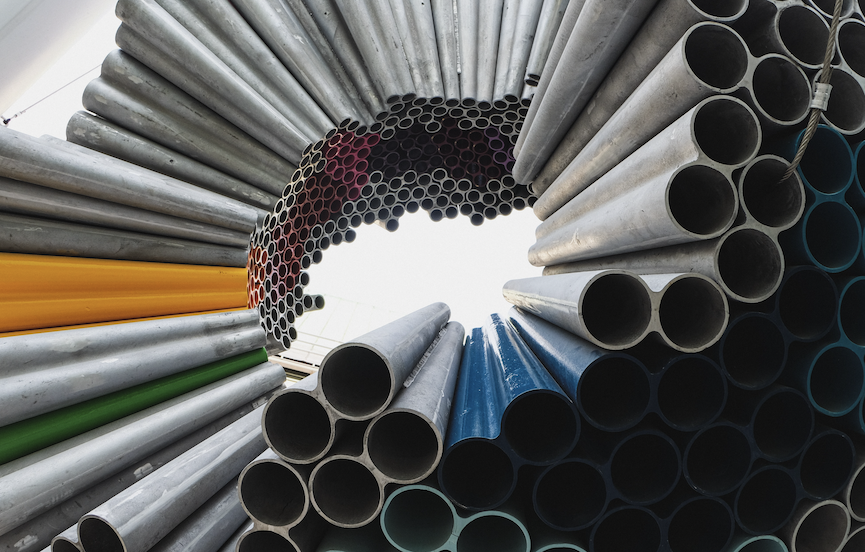

A highly used metal throughout the world, steel is not only super versatile, but it is also incredibly strong and cheap to make. It is no surprise then that the production of steel regularly tops 750 million tones each year. After cement, steel is the second-highest mass-produced product in the entire world. You can view a varied range of steel products here.

Unlike some other construction materials, steel is fully recyclable and does not use a great amount of energy in its production process. As a result and because steel production has cleaned up its act over the last few decades, it is a sustainable and environmentally friendly material to use.

The type of products that are made from steel vary greatly and include things like forks and knives, railroads, razors, bridges, gas and oil pipelines, ships, surgical instruments, automobiles, elevators, and skyscrapers. It is clear to see then that the stuff is everywhere.

History

Iron is one of the most widely abundant elements on the planet, with it making up in excess of 5 percent of the Earth’s crust.

Humans first started making steel all the way back in 2000 BC in the continent of Asia. This is where the term the Iron Age came from. During this time, iron replaced bronze for the purpose of producing weapons and tools. What was created during the Iron Age was wrought iron and was made by trained blacksmiths that would heat up the iron to temperature where it was malleable and then hammer out any of the impurities on top of an anvil. As a result of this process, the iron produced from it was not only very tough but also malleable.

It was during the Middle Ages that a brand new type of iron was forged under even higher temperatures than before. This produced what is known as cast iron and was even harder then the wrought iron that was its predecessor. However, it was more brittle.

Until steel began to be mass produced in 1870 AD, it was iron that formed the basis of all the materials used in human civilization prior to that.

Composition

When carbon and iron come together, they produce the alloy that we know to be steel. In some instances, it may contain small traces of oxygen, sulfur, phosphorus, and silicon.

The amount of carbon that is typically found in steel ranges from between 0.08 percent at the lower end and 1.5 percent at the higher end. Because of this, steel is much stronger than what wrought iron is but less brittle than cast iron. It is clear to see then that steel has a very unique blend of tensile strength, flexibility, and hardness – it is this that sets it apart from other metals and why it is ideal for construction purposes.

It is made by heating and melting iron inside of a furnace so as to remove any impurities that are in there and so that carbon can be added.