As the global population reaches the 8 billion mark, combating hunger and food distribution remains one of our most crucial challenges. While genetically modified seeds, agriculture and food technology, and other modern inventions have ensured that the world is producing enough food to feed all of the 8 billion people, up to 800 million of the global population is still struggling with hunger.

According to the World Food Program, factors like the Covid-19 pandemic and the Ukraine war have caused an acute food crisis, affecting another 200 million more people globally than in 2019. So essentially, up to 1 billion of the 8 billion population is facing food shortage, insecurity, or acute hunger!

And while this happens, nearly one-third of all food produced each year gets spoiled before it can be consumed.

Unsurprisingly, India ranked 107 out of 121 countries in the Global Hunger Index 2022. With the level of hunger labeled as ‘serious’ in India, it is disturbing to find that India incurs post-harvest losses estimated of up to 25% for perishable foods like milk, fish, and eggs and 30%-40% for fruits and vegetables. We produce 400 million MT of perishable food every year and the annual value of losses in the agri-produce alone stands at Rs 92,651 crores. A country battling high hunger rates cannot afford to lose 40% of its food to supply chain issues.

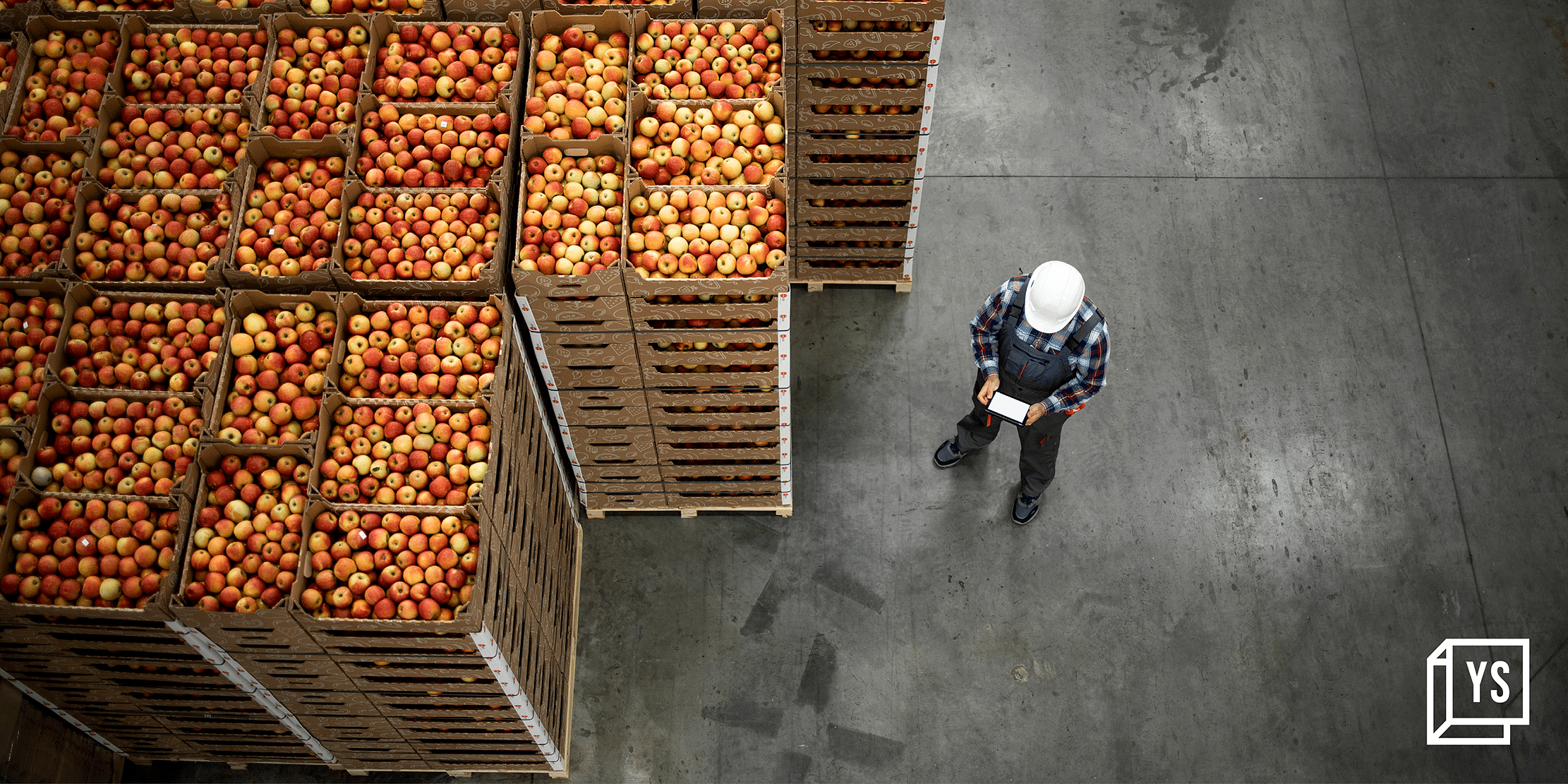

Image: Shutterstock

While creating efficient temperature-controlled logistics is the need of the hour, it is not enough to address the scale of the problem. Upgrading the existing infrastructure to build a tech enabled, effective, and unbroken cold supply chain that can impact effective food distribution is the way forward to create impact and arrest the losses–both in quantity and revenue.

However, currently, the cold supply chain in India is highly fragmented with poor infrastructure and tech integration. In order to improve the hunger index ratings, to ensure superior quality of produce reaches maximum consumers, while helping farmers get the fair price for their efforts, the temperature controlled cold supply chain needs to evolve and be integrated through tech adoption, to eliminate existing bottlenecks.

Here are a few benefits of how an unbroken cold supply chain can help fight inefficiencies in the food supply network and eliminate wastage:

Efficient food distribution

Much of the food products’ quality and shelf life are compromised by the time they reach the market. Farmers incur heavy losses as the products become unfit for consumption caused due to temperature fluctuations and damage and decay. A technology-driven supply chain promotes consistent temperature monitoring, real time updates, live tracking and thus effective distribution of good quality produce, irrespective of the time and distance. Additionally, a robust cold supply chain that facilitates improved delivery routes and better demand forecasts will also ensure efficient and effective food distribution.

Enhanced reach to new markets

Inadequate cold supply chain infrastructure means perishable products can travel only a short distance, leading to unequal distribution of food. Challenges like temperature fluctuations during the loading and unloading of goods at different points can lead to damage of perishable food, and thus limit the market reach while also forcing farmers to sell the produce at cheaper costs to avoid wastage. An efficient cold supply chain that utilises intermodal transport and advanced technology ensure products can travel longer distances without being affected by changing atmospheric conditions. Products stay fresh for longer periods, enabling farmers to confidently tap into new markets, ensuring not only an increase in revenue but also effective food distribution.

Promotes better inventory management

Enhanced, tech-enabled visibility into the supply chain plays a pivotal role in data driven insights about the quality aspects on-site, off-site, and in transit with the help of tech integration. With accurate stock data at all stages of supply, businesses can manage inventory more efficiently. Stock accuracy is especially critical for short-shelf-life products, and wider collaboration with all the stakeholders which helps remove uncertainty, optimizes stock levels, and prevents food wastage.

Enables a better supply chain strategy

Poor cold supply chain strategies are one of the leading causes of food wastage. Data insights are critical to implementing robust supply chain strategies. A well-managed cold supply chain with the support of advanced technology gives access to past and current food supply chain records, which enable suppliers to respond to future events, forecast fluctuations in demand, and crises. Businesses can predict seasonal peaks and shortages with the help of past data, equipping them with better response plans and more effective allocation and distribution of food products. ‘

Hunger is not about lack of food but is directly connected to effective food distribution and arresting food wastage. A strong cold supply chain infrastructure across key locations in the country would be the first and most critical step to address the above two crucial aspects contributing to hunger. With tech integration, it is possible to build end-to-end visibility of perishables and efficient last-mile deliveries, allowing businesses to curb food wastage and revenue losses. Delays in deliveries in remote areas and decay and damage during transportation will be a thing of the past if cold supply chain facilities in our country are optimised and utilised to their full potential.

(Disclaimer: The views and opinions expressed in this article are those of the author and do not necessarily reflect the views of YourStory.)

![Read more about the article [Startup Bharat] Why this agritech startup believes the future of farming is in hydroponics](https://blog.digitalsevaa.com/wp-content/uploads/2021/06/imageonline-co-logoadded38-1623755710158-300x150.jpg)

![Read more about the article [Funding alert] Peter Thiel’s Valar Ventures leads $75M Series B round in B2B commerce platform ShopUp](https://blog.digitalsevaa.com/wp-content/uploads/2021/08/funding-shutter1-1627838959269-300x150.png)