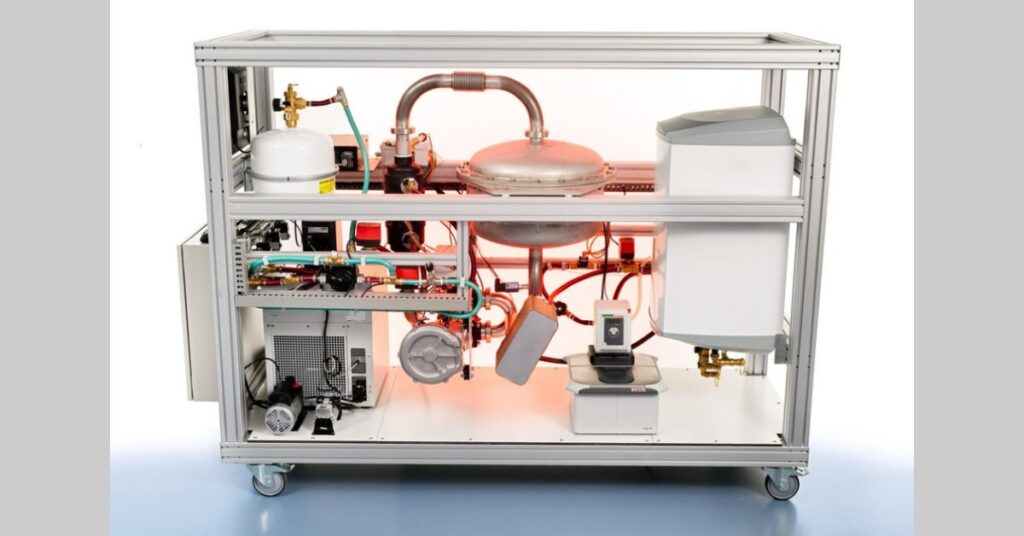

Olaf Adan at the latest heat battery prototype | Image Credit: Vincent van den Hoogen

The Netherlands might have finally found a solution to its quest to make millions of homes gas free. A new heat battery, developed by a consortium of Eindhoven University of Technology (TNO) spin-off Cellcius and industrial partners, aims to be a cheap, compact solution in the energy transition being targeted by the country.

With the Russian invasion of Ukraine having entered its third month and Moscow having cut gas supplies to Poland and Bulgaria, there is an increased need to take homes off gas. As part of its Climate Agreement, the Netherlands has set a goal of implementing 1.3 million heat pumps by 2030. The country is, however, expected to fall short by no less than 4,00,000 and this heat battery solution can act as a quick and large-scale solution.

Has the Dutch workforce mastered all digital skills? Find out

Eindhoven heat battery solution is built on a simple formula

Olaf Adan, TU/e professor and principal investigator at TNO, has demonstrated his simple experiment revealing the essence of the heat battery multiple times. He reveals how filling a small bottle with white salt grains, adding a little water causes it to sizzle. The bottle also instantly feels hot. The new Eindhoven heat battery solution is also built on this simple thermochemical principle: the reaction of a salt hydrate with water vapour.

“The salt crystals absorb the water, become larger and, in the process, release heat,” says Adan.

This chemical exchange leads to the bottle staying warm and the reverse is also possible wherein you can add heat to evaporate the water and dry the salt. He says as long as there is no water getting to this dry salt powder, the heat is always stored in it. The resulting product is a battery that is completely loss-free.

Adan says the process can be repeated endlessly and becomes the basis for a heat battery capable of storing heat that can be used at a later time or in a different place. He sees this as a solution for the fluctuating supply of renewable energy in homes and buildings, and as a medium for the reuse of ‘heat waste’ in another place.

While it looks simple, the biggest challenge is the use of the right salt material and Adan, who has been working on this for over twelve years, says only a “very limited number have the right properties for use in a battery.”

“A salt crystal like that gets bigger and smaller, heat goes in and out all the time. So something happens to such a particle. As a result, it can quickly disintegrate or clump together with other particles. So you need a material that you can continue to use cyclically,” says Adan.

He and his team settled on potassium carbonate as a basis and built a closed loop system, a recirculating system consisting of components including a heat exchanger fan, evaporator/condenser, and a boiler with salt particles. With a European subsidy of seven million euros, Adan and his team have built a prototype heat battery that is ready for its first real-world tests.

Optimised for real-world use

The prototype entering the real-world test looks sort of like a large cabinet with dozens of lockers and has multiple loose cables sticking out of the side. Each duo of small lockers matches the dimensions of the original demonstrator and the whole device has a total of 30 such lockers with a total storage capacity of over 200 kWh. Adan says that capacity is equivalent to two fully charged Tesla.

By redesigning the individual components such as the evaporator and heat exchanger, Adan and his team have managed to build a modular system wherein those small units can be combined at will. With each locker being its own individual unit, the team behind this heat battery sees the possibility for different designs, shapes, and sizes.

“It is not yet a product, but everything is now ready to be tested for the first time in a real-world situation,” adds Adan.

The testing is beginning with a battery of about 70 kWh being installed in four homes – two in Eindhoven, one in Poland, and one in France. They say that this battery is capable of lasting for at least a few days without sun or wind. Through this real-world test, they aim to learn about what else is needed for this battery to be used as a large-scale solution in over three million Dutch households.

From heat battery to heat transport

Adan and his team began this experiment with the idea of building a heat battery that can work as a storage medium in homes. However, they realised that this thermal battery can store heat loss-free and then decided to study about it being transported loss-free as well. The key thing to know here is that nothing happens to this heat battery till the time water is not added to the dry salt.

The team at Eindhoven University of Technology (TNO) sees thermochemical principle as not just a way to store heat but also a way to transport heat without any loss. This would be a game changer when you consider the fact that heat transport, through pipes or phase transitions, always runs into losses.

The consortium is also studying industrial residual heat as a heat source, a kind of ‘heat waste’ that is generated as a by-product in factories or surplus heat from data centres. Adan is running a real world test for this heat battery test as well where the residual heat from the “Chemelot Campus in Sittard-Geleen will be transported to about fifty homes in the neighbourhood in the same municipality.”

Adan explains, “With a heat recharging station at SABIC we collect heat and dry the salt. We then drive this salt by truck to a sort of ‘transformer house’ in the residential area, from where the fifty homes are supplied with heat via pipes. So we don’t have to be in the homes themselves.”

Moving beyond technology

Adan and his team at spin-off Cellcius, the first combined TNO and TU/e spin-off, have demonstrated the ability of their heat battery technology to act as a storage and transport medium. Now, they are looking at the next major step in their journey – turning this into a product.

It has received a seven-figure European grant and has secured additional funding as well to realise the residential pilot project. With recent investments from the Brabant Development Corporation, Innovation Industries and the GoeieGrutten Impact Fund, it has been able to put final touches to the financial aspect of the heat transport project.

“While the potential is great, we have also seen many great potential technologies that have not made it. So we’re going to keep our feet on the ground and take this one step at a time. I’m only in this for one thing: it’s great to be able to contribute to the energy transition,” Adan says.

Catch our interview with Paul Down, Head of Sales at Intigriti.