Electric vehicles (EVs) have been riding the popularity curve for the past few years. Marketed as a solution to vehicular pollution, EVs have taken the world of automotive industry by storm, giving fuel-powered cars a run for their money.

These EVs run on lithium batteries—cells made primarily from Lithium, Nickel, and Cobalt—critical metals with complicated environmental and human concerns associated with their mining.

However, like every other battery, these batteries have a life cycle, which depends on factors such as usage patterns, charging habits, and storage conditions.

So, what happens to these batteries once they have reached the end of their lifecycle? While some batteries are improperly disposed, which can pollute the environment and harm plants, animals, and humans, other batteries are recycled.

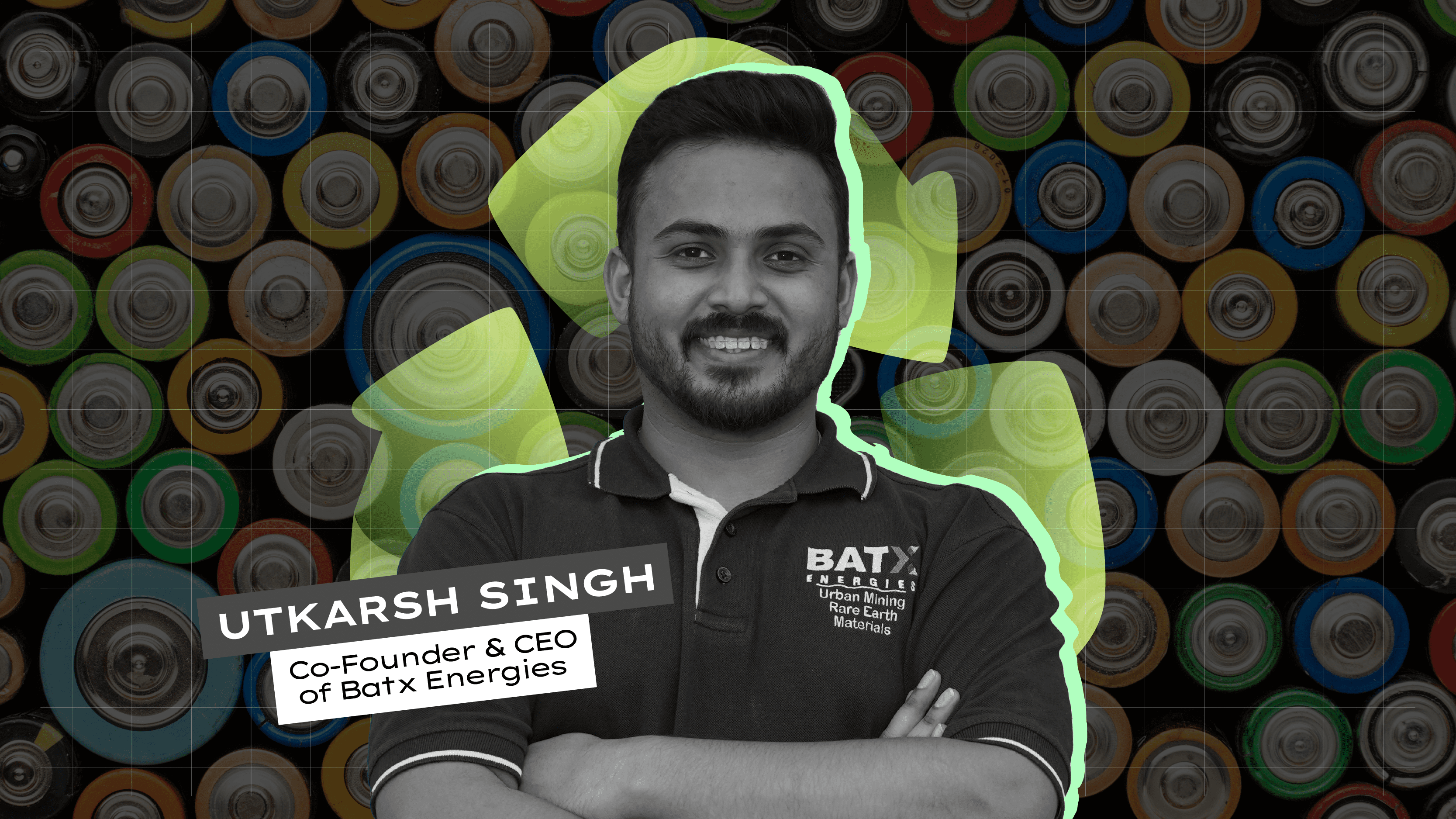

This is where the technology developed by BatX Energies comes in. The Gurugram-based startup, founded by Utkarsh Singh and Vikrant Singh in 2020, recycles lithium-ion batteries to mine critical minerals like lithium, cobalt, and nickel, which is then used to make new lithium batteries.

The minerals needed to make these batteries are currently unavailable in India, creating a massive demand for imported materials from other countries, particularly China.

“As a company, we have taken the initiative to mine these minerals,” says Utkarsh Singh, CEO, BatX.

BatX is looking to raise $30 million by the end of this financial year, and is in talks with active investors. The founder confirmed that the company is also looking to raise $3 million in a bridge round this quarter.

BatX Lab

What does BatX do?

The startup has three products in its portfolio—black mass, rare earth metals, and secondary by-products, which include high-grade plastic and aluminium sold to recycling companies.

According to Utkarsh Singh, the company’s black mass has seen widespread popularity among its clients. Black mass is a mixture of valuable metals, including lithium, cobalt, nickel, and manganese, produced while recycling used lithium batteries.

BatX has developed an in-house proprietary process that produces black mass with less than 1% impurities, giving the startup a competitive edge in the space.

“We have focused and worked on how we can increase the yield of lithium and nickel from waste to 95%. That is our first competitive edge, wherein our other competitors are somewhere around 85 to 87%,” Singh tells YourStory.

He adds that building everything in-house is critical to controlling costs while operating a capital-intensive process. BatX has not brought in any machinery from outside and has not imported any parts to develop the process.

“This (innovations) has only happened because this is the only thing we know. After our college, we have not done anything else,” says Singh.

The startup, which currently operates as a 48-member team, has recycled around 220 million batteries till now.

Sourcing the batteries

BatX spends most of its capital sourcing used batteries, either from EVs or consumer electronics. The company currently has provisions to source batteries from anywhere in the country and has set up a network in other countries like Malaysia, the United Kingdom, Germany, and the Philippines.

A request raised in any of its operating regions is connected to the company’s partners in that location. Once the request is raised, the company confirms how much energy is remaining in the battery—batteries with higher energy cost more than those with lower energy. The company then ships these batteries to its processing plants in India to recycle.

Batteries are sourced broadly from two sectors—the organised sector and the unorganised sector. They are either from electronics or electric vehicles.

Getting the sourcing ecosystem correct was one of the main challenges BatX faced initially.

According to Singh, 80% of lithium used in electronics items is sourced from the unorganised sector for recycling, and only 20% is from the organised sector. While in the case of EVs, 80% is sourced from the organised sector and 20% from the unorganised sector.

“The batteries which are sold today will come into the market for basically three years down the line. So, currently, if you look at the number of batteries in the market, you’ll have to look at data from three years ago, which was pretty less compared to what it is right now. So right now, they are also sourcing batteries from other sources, such as consumer electronics, telecom towers. But eventually, we feel that this battery market will get organized,” says Om Pawaskar of Zephyr Peacock.

According to data website Tracxn, Zephyr Peacock currently holds a 9.9% stake in BatX, and Pawaskar is an investor and board observer at the startup.

BatX co-founders Utkarsh Singh (L) and Vikrant Singh (R)

How it all began?

BatX was established by Utkarsh Singh and Vikrant Singh based on a thesis they worked on during their engineering college days.

While in college, students were encouraged to participate in competitions requiring them to build their own engines and participate in races using these engines. However, in 2017, all these norms changed and ICE engines were not allowed to compete in these races. Students were then forced to look outside conventional engines, and their attention turned to EVs.

The beginning of BatX can be traced back to those days.

Today, BatX can process around 65 EV batteries in a day, depending on the weight of the battery and its usage. The company plans to set up two more plants, one in Tamil Nadu and the other in Karnataka.

The market and way ahead

The Indian EV market is forecasted to grow from $3.21 billion in 2022 to $113.99 billion by 2029, with an expected compound annual growth rate (CAGR) of 66.52%, according to a report by India Brand Equity Foundation published this year.

The growing demand for EVs in India coupled with the lack of mineral deposits in the country to manufacture batteries creates a unique opportunity for Lithium battery recycling companies like BatX to enter the market.

Some of the other players in the market include Roorkee-based Attero and Noida-based LOHUM.

BatX is currently working towards bringing its higher-capacity hydrometallurgy plant live and expanding its black mass production capacity to 10,000 metric tonnes from the current 3,000 metric tonnes.

It is also working on completing research and setting up the Cathode Active Material (CAM) manufacturing plant. CAM, a combination of metals that BatX already mines, including cobalt and nickel, is a crucial component in lithium-ion batteries. The company will soon start supplying CAM to battery manufacturers, who will coat it and make it electric.

The plant is set to finish being built this year, and production is set to begin in the first half of 2025.

According to Utkarsh Singh, the company is doubling down on expanding its capacity from its current metal extraction of 12,000 metric tonnes in the next five years, giving it a top line of around Rs 110 crore.