When it comes to quality checks (QC), human error is a complex and costly challenge. According to a study by Vanson Bourne, manufacturers understand the pain of unplanned downtime due to human error better than any other sector. The study also revealed that nearly half (45 percent) of manufacturers realised that there is room for improvement when it comes to preventing problems with assets in their organisation.

The manufacturing industry is also undergoing a seismic shift towards optimisation and smarter systems and processes. Many organisations are moving towards specialised manufacturing by offloading part manufacturing. This allows for lesser control over the quality of parts that they use.

On the other hand, part manufacturers face constant resistance with the prospect of batch rejections. Visual quality checks are necessary across a variety of industries in manufacturing. Furthermore, Measurement System Analysis standards mandate visual inspection to have 98 percent sensitivity in terms of accuracy. With manual inspection however, the output is inevitably always lower. With the subjectivity bias always in the backdrop of such decisions, the risk of a customer complaint and the high costs associated with false rejections are very high.

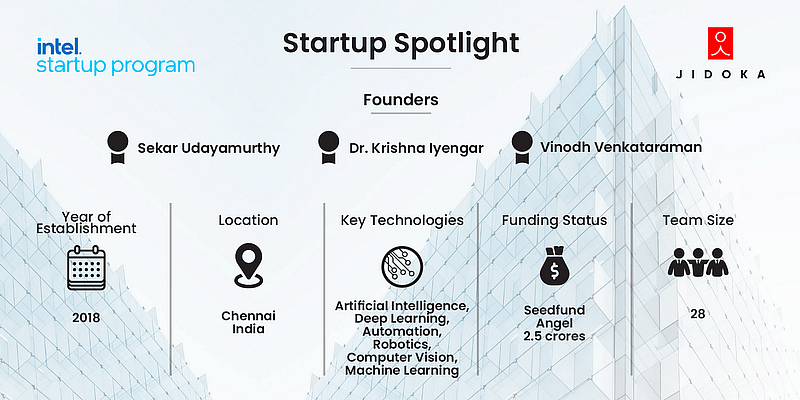

Recognising the tremendous opportunity for automated QC solutions, Sekar Udayamurthy, Dr Krishna Iyengar and Vinodh Venkatesan founded Jidoka Technologies, a computer vision and artificial intelligence company, with a mission to bring AI into the mainstream in manufacturing and make automation in visual quality control practical and useful for manufacturing companies.

Automation with human touch

The Japanese term ‘Jidoka’ stands for a principle that advocates ‘intelligent automation’ or ‘automation with a human touch’. The founders bring a combined experience of over 40 years in the field of engineering, technology and IT.

Jidoka had its first customer in the latter half of 2019, and has expanded exponentially to 12 customers in just two years.

“We positively impact our customers by increasing their throughput by 33 percent and accuracy by 5-8 percent, and decreasing their false positives by 30 percent. The ROI for customers is less than 15 months too,” said Sekar, CEO and Co-founder, Jidoka Technologies.

We are now using the experience we have gained in auto vertical and are building verticalised solutions for food and pharma, general manufacturing and other industries,” he added.

How Jidoka helps address the problem

Being an E2E solution provider, Jidoka’s state-of-the-art solution combines the power of AI with automation and computer vision in defect detection, delivering over 98 percent accuracy in the QC process.

Jidoka’s QC solution has two parts, both hardware and software components. The hardware platform has three trademarked structural shells or a custom-made product architecture, where it delivers the right solution for products – Huron for large volume complex products, Tigris for flat and lightweight products, and Miyake for manual load and unload with selective checking.

Jidoka’s software platform, Kompass, marries real-time decision making with state-of-the-art AI to create an end-to-end system for visual defect systems. The software provides a turnkey solution that fits seamlessly into the production line of different manufacturers. The system also uses a digital twin created by the hardware and maps it to the AI to deliver up to 250 decisions per minute.

Ensuring production lines run 24X7

Humans, even the best of them, are prone to inconsistent output due to factors like fatigue, monotony, sickness, and more recently social-distancing. Moreso, the manual inspection processes cause wasteful rejection, such as false positives and restricted throughput, because of QC backlogs. Furthermore, if the quality of products is not up to the mark, the consequent drop in customer satisfaction and trust can be very expensive.

Jidoka helps manufacturers address this through a hybrid of supervised and unsupervised Computer Vision AI algorithms. In the low data regime, it uses a patented Anomaly detection algorithm along with clustering. The startup’s image data augmentation aids supervised AI algorithms like image classification, object detection with regression algorithms for model testing, monitoring and MLOps.

“Organisations which have adopted these have seen significant reduction in costs and increase in customer satisfaction. Additionally, higher flexibility, scalability, reduction in error due to automated visual inspection, lesser wastage and elimination in downtime are also seen,” said Sekar.

“When the industrial safety management system is additionally integrated, it eliminates shop floor accidents too,” he added.

How the Intel Startup Program powered Jidoka’s growth journey

“Intel has helped optimize our Edge devices to be more performant for our AI use cases, and educated us on leveraging the MLOps platform which we have since adopted. On the business front, we have been onboarded to the Plugin Alliance (an industry technology alliance), giving us visibility with enterprise customers and best practices from Industry 4.0 perspective,” said Sekar, endorsing the Intel Startup Program.

“The breadth of ecosystem support from a startup perspective and depth of technical knowledge to support varied use-cases has been the backbone of our relationship and it has been immensely useful to us. We would certainly encourage other aspiring entrepreneurs to be a part of the Intel Startup Program and gain from their expertise and experience,” he added.

How the Intel Startup Program is enabling startups to scale their game-changing innovations

The Intel Startup Program is Intel India’s flagship program to engage with technology startups who have an IP or innovative solutions that have the potential to create impact on customers and align with Intel’s focus areas. The program is at the forefront of engaging with India’s startup ecosystem through high impact collaborations with the industry, academia and government and runs multiple initiatives that are either vertically aligned or focused on emerging technologies.

It engages with startups that have a unique global or local value proposition to solve genuine customer problems, enabling them with domain and business expertise from the industry and mentorship from Intel.

For more details visit: https://www.intel.in/startup-program

![Read more about the article [Funding roundup] Hudle, Snooplay, TruBoard Partners raise early rounds](https://blog.digitalsevaa.com/wp-content/uploads/2022/07/Images51u-1657020995722-300x150.jpg)