Clean mobility ecosystem player, Micelio, on Friday held its third Global Clean Mobility Summit in Bengaluru. At the event, it launched a report addressing India’s battery ecosystems and identifying unique challenges and laying out the paths to address these problems.

The report, titled “Evolving Ecosystems: Unlocking the Potential of India’s Domestic Battery Value Chain”, was a collaboration between Micelio, nonprofit organisation RMI, and the entrepreneurial hub at IIMB, NSRCEL.

India is currently seeing rising adoption of electric vehicles (EVs) with current penetration standing at 6.8% in FY23-FY24. Going forward, with the rollout of favorable government policies such as PM E-drive, new EV vehicle sales are expected to touch 30% by 2030, the report says.

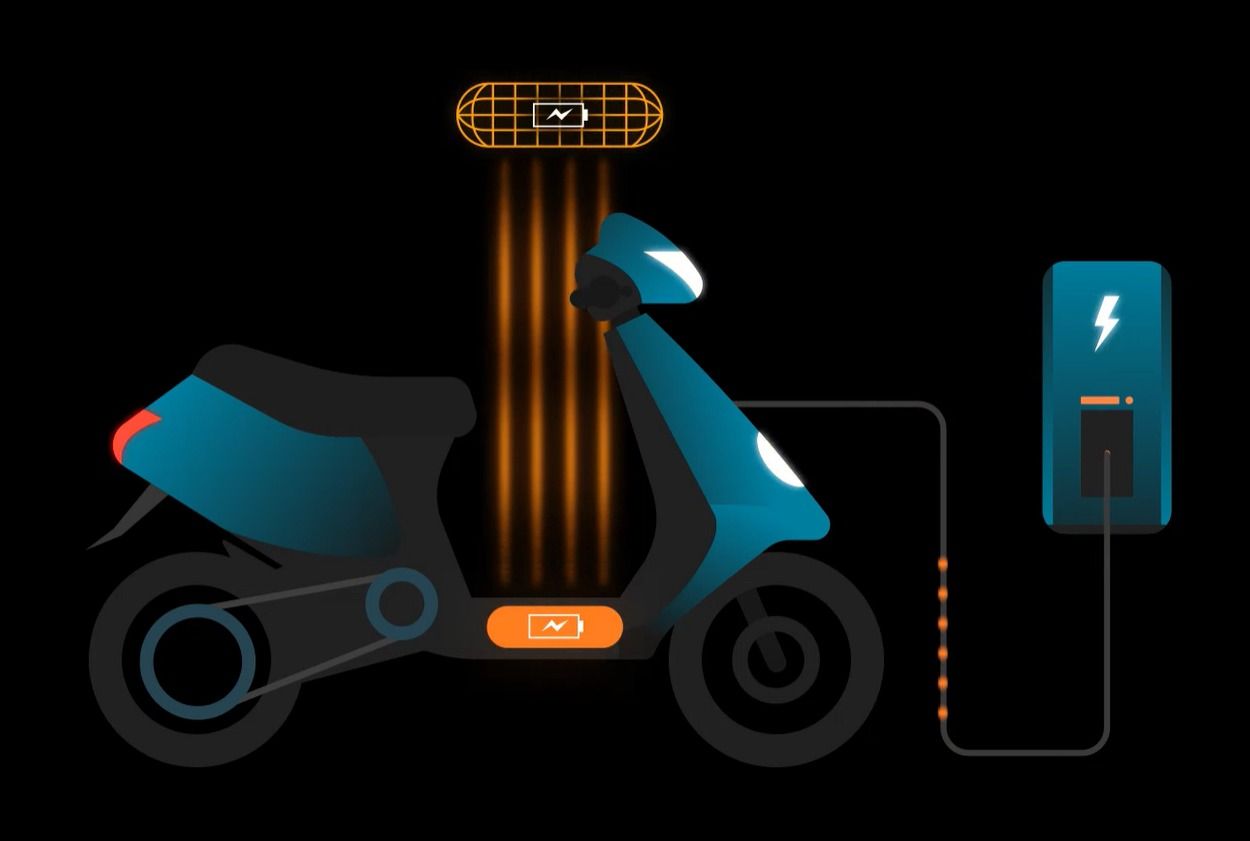

At the core of this rising transition to EVs are batteries. Innovation in battery technology is an important step and India is making strides towards developing this ecosystem with the help of several government initiatives such as Khanij Bidesh India Limited (KABIL) and Production Linked Incentive (PLI) scheme for Advanced Chemistry Cells (ACC) to promote domestic battery production by 2030.

However, the ecosystem is not without challenges. India imports 100% of its lithium needs and 70% of its cobalt and nickel, primarily from China, which dominates 80% of the global lithium refining market. The report addresses this challenge and suggests that while India explores more lithium reserves, the Ministry of Mines can work towards forming stable partnerships with countries to source lithium and cobalt to mitigate supply chain risks.

India needs over $10 billion in investment to develop needful infrastructure refining and gigafactory infrastructure for battery production. This can be addressed by leveraging public sector undertakings (PSUs). By leading investments, PSUs can lower barriers for private sector players to scale up operations, the report says.

Quality issues in batteries are a key sticky point in today’s EV ecosystem. Imported battery materials, including raw materials, cells, and other elements are assembled into battery cells and/or packs. These often have quality issues, reducing their lifespan by about 30%. This inconsistency also increases maintenance costs for EVs, affecting consumer confidence in these vehicles.

The report addresses this problem by suggesting that the Indian Bureau of Standards (BIS) and local battery manufacturers develop and implement a battery grading framework. The guidelines would define performance benchmarks and quality parameters specific to the Indian market.

With the rising influx of EV batteries in the ecosystem, there comes an increasing need to promote a circular economy in the EV ecosystem. However, today, India’s recycling rates are below 5%. Rather than missing out on oppurtunities to reclaim valuable materials like lithium and cobalt from these batteries, the report suggests the development of a Battery Traceability System, a form of Battery Aadhaar.

Under the system, each battery will have a unique identification number which enable real-time tracking for its entire life cycle, from production to disposal.

To facilitate these problems and encourage collaboration among various stakeholders, RMI plans to form a battery consortium to bring together manufacturers government agencies, research and financial organisations to deploy solutions to help localise production, promote a circular economy, and improve resource efficiency.

![Read more about the article [Funding alert] Luxury chocolate brand SMOOR raises undisclosed funding from Klub](https://blog.digitalsevaa.com/wp-content/uploads/2021/07/Chocolates-1626088239815-300x158.jpg)

![Read more about the article [Funding alert] Neobank Jupiter raises $44M ahead of its public launch](https://blog.digitalsevaa.com/wp-content/uploads/2021/07/FHD-87701561969596325-300x150.png)