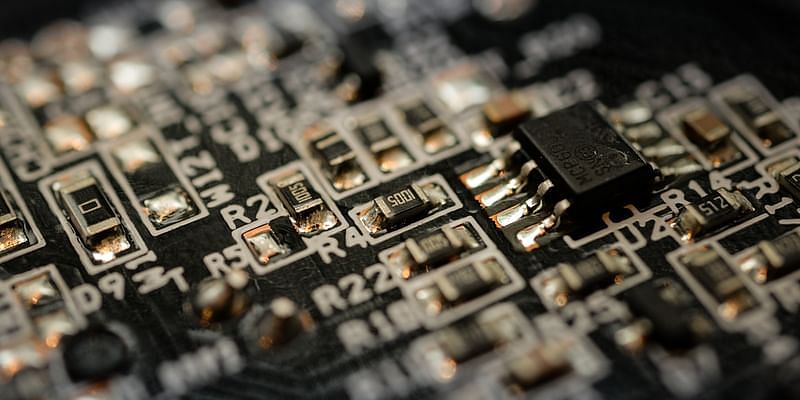

Over the years, semiconductor chips have caused a massive disruption in every facet of the industrial landscape, transcending beyond a mere tool to becoming the building blocks of all sectors of the economy.

Standing at the threshold of digitisation and innovation, semiconductor chips have penetrated deep into the peripherals of aerospace, automobile, communication, IT, clean energy, and defence, among other sectors, marking the advent of the tech revolution.

Poised to drive the next phase of the digital revolution under the illustrious Industry 4.0, the semiconductor chip landscape is actively undergoing a wave of paradigm shifts.

With transformation at the forefront, this ground-breaking revolution will be characterised by advancements in architecture, materials, artificial intelligence (AI), 3D technologies, memory systems, and the integration of CMOS and MEMS.

As we progress further, the future of chip manufacturing promises unparalleled efficiency and innovation.

.thumbnailWrapper

width:6.62rem !important;

.alsoReadTitleImage

min-width: 81px !important;

min-height: 81px !important;

.alsoReadMainTitleText

font-size: 14px !important;

line-height: 20px !important;

.alsoReadHeadText

font-size: 24px !important;

line-height: 20px !important;

New chip architectures in the market

For over five decades, the X86 architecture has been the bedrock of the microprocessor industry. However, the industry has recently witnessed a change with ARM architecture making significant strides in the market.

Noted for its impressive performance and low electricity consumption, ARM is reshaping chip design by licensing its IP to manufacturers for further development and production in foundries.

Boasting a RISC-V architecture, being open-source and energy-efficient, it is increasingly becoming prevalent in IoT devices and other applications.

Dynamic material to complement silicone base

Although silicone has been the standard base material for microchips, recently, it reached its performance limit leading the industry on a quest for smaller, faster, and integrated circuits.

The exploration for emerging materials, namely gallium nitride—commonly used in power grids for effective power conversion—also contributed to the need for improvised circuits.

Microchips leveraging antimony and bismuth are proactively enhancing infrared sensors in medical and military sectors. Graphene possesses the potential to outdo silicone, though its widespread commercialisation is years away.

Further, Pyrite is also emerging as a viable substitute for rare earth elements in solar cells, offering an abundant, economical, and non-toxic alternative.

Embracing smart technologies: The AI edge

As AI grows at an unprecedented pace, it will also play a revolutionary role in transforming the chip ecosystem. By embedding learned knowledge in IoT endpoints, AI chips are achieving much better efficiencies.

However, to holistically implement IoT, research is capitalising its focus on achieving efficiencies of 10,000 TOPS/W, utilising expedited GPUs and AISCs for computations.

.thumbnailWrapper

width:6.62rem !important;

.alsoReadTitleImage

min-width: 81px !important;

min-height: 81px !important;

.alsoReadMainTitleText

font-size: 14px !important;

line-height: 20px !important;

.alsoReadHeadText

font-size: 24px !important;

line-height: 20px !important;

3D technologies enabling heterogeneous integration

Heterogeneous integration, which seamlessly combines diverse electronic components on a single chip, is pivotal for overcoming memory limits, simultaneously, enhancing functionality in compact systems.

3D integration technologies can be a game-changer, playing a key role in putting efforts to reduce junction distance between solder balls or micro bumps. With accelerated efforts, the advent of IMEC’s seven-micrometre junction distances has enabled a 3D junction density of over 16 times, which has significantly reduced the required space.

Robust amalgamation of CMOS and MEMS

In the coming years, the semiconductor chip manufacturing industry will witness an increasing synergy between established CMOS technologies and MEMS (micro-electromechanical systems).

CMOS wafers—containing control and readout circuits, signal processing, and interfaces—serve as intelligent substrates for MEMS. The future looks promising as the dynamic combination will pave the way for cost-effective, compact micro-systems, which will prove to be invaluable in an array of sectors, from medicine and mobility to aerospace.

A brighter future

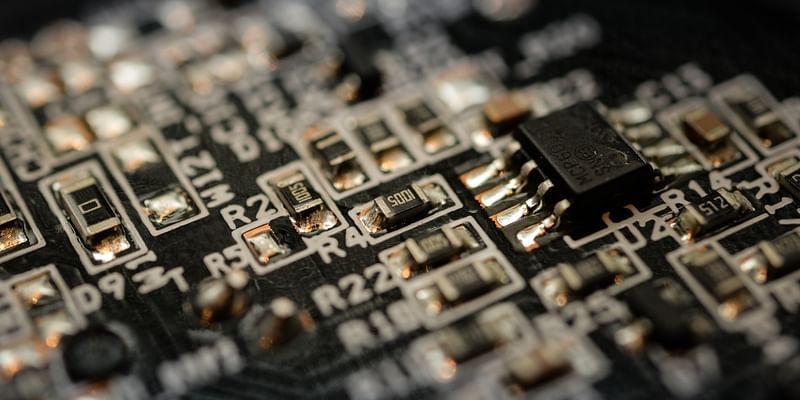

Undoubtedly, the semiconductor chip landscape is at the cusp of a revolution. Driven by innovative architectures, materials, AI advancements, 3D integration, memory technology developments, and the fusion of CMOS and MEMS—the industry is poised to venture into a future marked with greater efficiency and effectiveness.

With smaller form factors and broadened application scope, it will continue to refine its relevance in the technological landscape while carving the roadmap to paradigm transformation.

Shashank Donthi is the CEO of Semikart.

Edited by Suman Singh

(Disclaimer: The views and opinions expressed in this article are those of the author and do not necessarily reflect the views of YourStory.)