Since time immemorial humankind has heavily banked on fossil fuels for its energy needs. And while that served us well, it also vastly contributed to the aggravation of various kinds of pollution, worsening the effects of climate change.

Growing up in the suburbs of India, Saurabh Tembhurne, Co-founder and CEO of SoHHytec, had long witnessed human’s inevitable dependence on fossil fuels and how their usage is the major cause of pollution. He wanted to come up with an alternative.

“Being an innovation lover, I always wanted to build something of my own to create unparalleled environmental, social, and human impact value,” says Saurabh. With this intent and a strong entrepreneurial spirit that he inculcated during his IIT Bombay days, Saurabh set out to build a unique and viable solution to the problem.

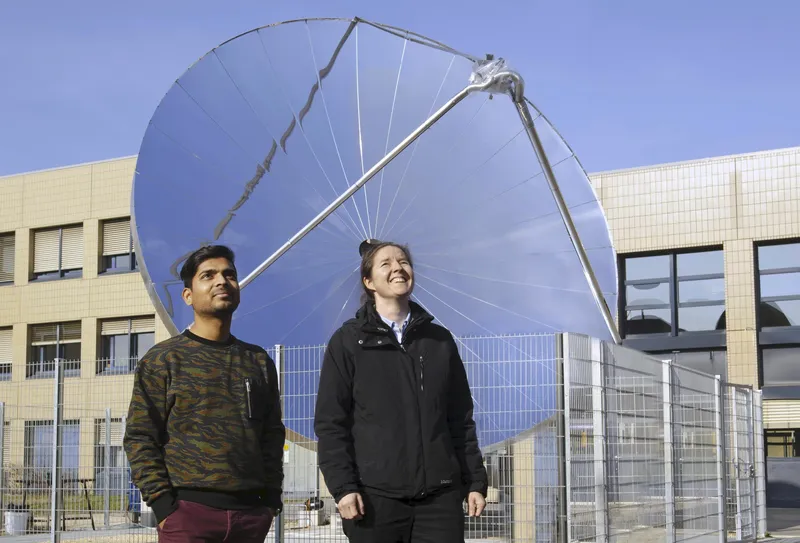

His quest led him to Switzerland where he pursued his Ph.D. in the field of solar fuels at EPFL (École polytechnique fédérale de Lausanne). Mid-way through his Ph.D. he invented a novel way of highly efficient, durable, and cost-effective solar fuel production. In 2015, along with his co-founder Prof. Sophia Haussener, he gathered up a team and started to focus on making the technology into an industrially deployable product.

Right after his Ph.D. with the support of the Swiss Innovation Agency and Swiss National Science Foundation, he started the pilot development of the product. Finally, in 2019, the first demonstrations with product-scale pilots were done and SoHHytec was officially born.

The solution

With growing concerns about climate change and air pollution, hydrogen is being increasingly seen as an integral component of the energy transition to a cleaner and more sustainable future. More importantly, green hydrogen that is produced using renewable energy sources such as solar, wind, or hydropower, instead of fossil fuels like natural gas or coal is considered a key technology in the transition to a low-carbon, sustainable energy system.

However, the majority of currently deployed hydrogen-producing machinery is based on fossil fuels, which is contrary to the purpose of having clean fuel. It’s also produced in a centralised way, which requires specialised and long-distance transportation eventually adding to further pollution, cost, and time for the end users.

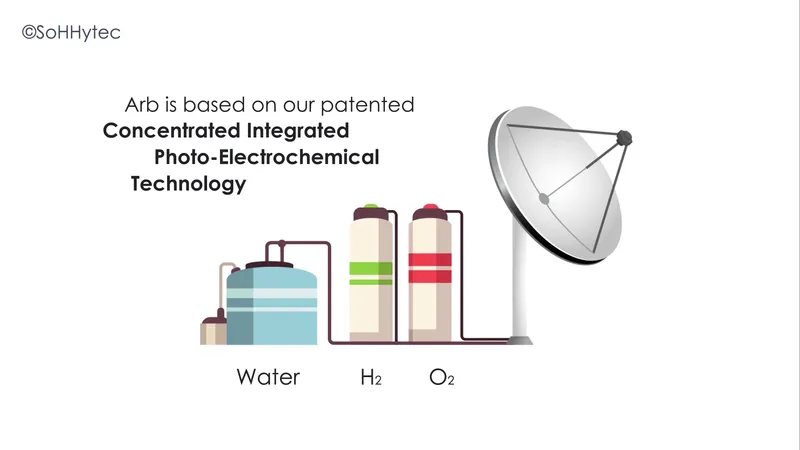

Taking all this into account, Saurabh invented an ‘artificial photosynthesis’ technology for solving the global problem of clean production of green fuels. The technology exactly mimics the process of photosynthesis in trees, where sunlight and water are taken as the input and fuel (Hydrogen) and energy (heat) are given as output. He named this artificial tree ‘Arb’.

“ The artificial tree called ‘Arb’ is a fully automated, plug & play system for solar fuel and power production having best-in-class durability and cost. Arb’s unique approach of taking only sunlight and water, and directly providing a clean and green fuel with unprecedented efficiency makes it fully self-sustainable and truly independent,” Saurabh says.

The magic sauce

Saurabh explains that the magic sauce of their invention is their patented ‘integrated photo-electrochemical device’ which enables the ‘Arb’ to take in sunlight and break the water molecule into hydrogen, electricity, and heat.

“This device performs the physics of sunlight absorption, and chemistry of breaking the water in a uniquely thermally synergistic and electrically integrated way which allows us to increase the efficiency of solar to hydrogen conversion by multiple folds,” he says.

The most convenient way of creating solar hydrogen is by combining solar farms (photovoltaic panels producing electricity) with an ‘electrolyser’- a component including peripherals – used to carry out electrolysis i.e. breaking water with electricity.

Saurabh apprises that in this process the physics of sunlight absorption to produce electricity and the chemistry of breaking water with that electricity happens in two separate components and places. “This is a loss-inducing power-electronics between the photovoltaics and electrolyser eventually making the PV powered electrolysis a low efficiency (~10 percent solar to hydrogen) and consequently costly endeavour,” he adds.

On the contrary, SoHHytec’s integrated photo-electrochemical device ensures that the physics and chemistry happen in the same device removing the need for any power electronics, and further allowing multi-physical optimisation to be performed. “Our device has demonstrated solar to hydrogen efficiency of ~25 percent (~2.5x than any other competing solar hydrogen production approach) along with fast dynamic response and long-term durability,” Saurabh says.

Scaling the solution

SoHHytec develops, builds, and operates gardens and forests of their ‘Arbs’ to offer hydrogen and power as a service to their end customers. They have three sizes of artificial trees to cater to the needs of their customers.

A garden of Arbs normally has 20 to all the way 100 Arbs. This modular garden layout is well suited for small-to-mid-scale industrial customers such as a steel processing factory or chemical processing plant.

“We deploy our small (9m) and medium (13m) Arbs for such Garden. The Arbs can be directly integrated into an existing layout while co-sharing available land (e.g a parking lot, industrial storage area, agricultural area). This solution offers unparalleled land co-utilisation capabilities. These gardens produce hydrogen which is directly used by steel or chemical processing factories as a raw material or as a fuel,” Saurabh explains. Additionally, the Arbs also give heat and pure medical-grade oxygen. The heat is directly supplied to the factory either for pre-heating, water heating, or even cooling needs, and oxygen to nearby medical facilities via a network of existing oxygen-gas suppliers. Such Gardens of Arbs can be deployed to create fueling/service stations for the logistic trucking industry, something that SoHHytec is currently working on building in the US.

Saurabh also says that going beyond a garden they can deploy forests (500 to 1000s) of Arbs for large-scale production of hydrogen. Such forests will be in areas where land availability is not of concern and land co-sharing is an additional plus. With forests of Arbs, big industries like steel manufacturing, and fertiliser manufacturing can be catered to and grid-stabilisation and grid-based energy storage can be provided.

“Our Arb is also a fully self-sustainable (requiring no external power at all) system for providing clean electricity production and long-term storage of that energy. In this context, gardens and forests of Arbs can power entire communities to villages and towns not only for their electricity production and storage needs but also for their hot water, heating/cooling, and medical oxygen needs,” he adds.

The road ahead

While SoHHytec’s Arbs aren’t currently available in India, Saurabh and his team are well on their way to starting their operations in the Indian market very soon. He believes that the patented integrated photoelectrochemical device will be a first-of-its-kind offering giving them the first-mover advantage and cost-effectiveness of the product will set a new benchmark for the hydrogen landscape.

“Our first goal is to prove to the Indian market how efficient and cost-effective the production of green hydrogen is with our Garden and forest of Arbs, as we have already done for Europe. Our main target is to offer Indian industrialists a way of decarbonising some parts of their industries sector with economic and energy saving”, he says.

India has ramped up its efforts to promote Green Hydrogen with the National Hydrogen Mission which was launched last year on August 15. Earlier this month, the Union Cabinet approved an initial outlay of Rs 19,744 crore for the mission.

Union Minister of Information and Broadcasting Anurag Thakur said that the country aims for the annual production of 5 million tonnes of green hydrogen by 2030, cutting about 50 million tonnes of carbon emissions and saving Rs 1 trillion on fossil fuel imports.

Guiding SoHHytec in their India journey is Swissnex, a launchpad for Swiss startups to expand into the Indian market. As a direct representation of the Swiss government in India, they are a zero-equity accelerator and have helped over 60 startups for their entry into the Indian market.

“We were part of Swissnex’s market validation camps and with the support of their team, we were able to navigate the tricky Indian market. We established solid industry connections which became a good starting point for us to start our “SoHHytec India Hydrogen Mission”. I am sure we will work closely with the Swissnex team in the years to come!”, says Saurabh.

Along with being a provider of Green Hydrogen, SoHHytec also sees itself positively influencing policy decisions for the Indian renewable / hydrogen economy. “Our aim is to empower nature by making the solutions of tomorrow available today. We believe our impactful solution will fuel the nation’s ambition for not only net-zero emissions but even beyond,” says Saurabh.

![Read more about the article [Startup Bharat] These 6 fintech platforms are bridging financial gap in non-metro cities](https://blog.digitalsevaa.com/wp-content/uploads/2022/03/Fintechfeaturesb-1648531906382-300x150.png)