It’s no secret that while electric vehicles (EVs) offer long-term savings by reducing expenditure on petrol or diesel, the benefits only start to pay off a couple of years down the road.

For most consumers, the long wait doesn’t justify the price tags of EVs, which can sometimes be 1.2 to 2.5 times higher than the cost of an ICE vehicle.

Minimines, a Bengaluru-based clean tech startup, says it has a solution that can potentially reduce the price of EVs.

The main culprit, responsible for the higher upfront cost of EVs, is the battery pack; in particular, the lithium-ion cells, which India currently imports from countries such as China and South Korea. EV batteries, in fact, account for up to 40% of the total cost of an EV, according to industry estimates.

To make EVs cheaper, it’s imperative that India produces its own lithium-ion cells, NITI Aayog’s adviser on infrastructure connectivity, transport, and e-mobility, Sudhendu Sinha, told YourStory in an earlier interview.

In the absence of very large lithium reserves (at least compared to China or South Korea), the easiest way for India to get the ball rolling on producing its own lithium-ion batteries is by recycling existing, defunct batteries, as well as other electrical equipment that contains the metal.

Currently, a majority of manufacturers dispose of their electronic waste, including batteries and battery components, by burning them at incineration facilities.

The few times the waste materials reach recycling centres, conventional extraction techniques like pyrometallurgy and carbothermal treatments often fall short of achieving complete metal extraction (because they result in amalgams or mixtures of elements and not the pure element itself), while also contributing to significant carbon dioxide emissions.

says it has developed a more efficient, environment-friendly process to extract and recycle lithium and other precious metals from batteries and other industrial byproducts.

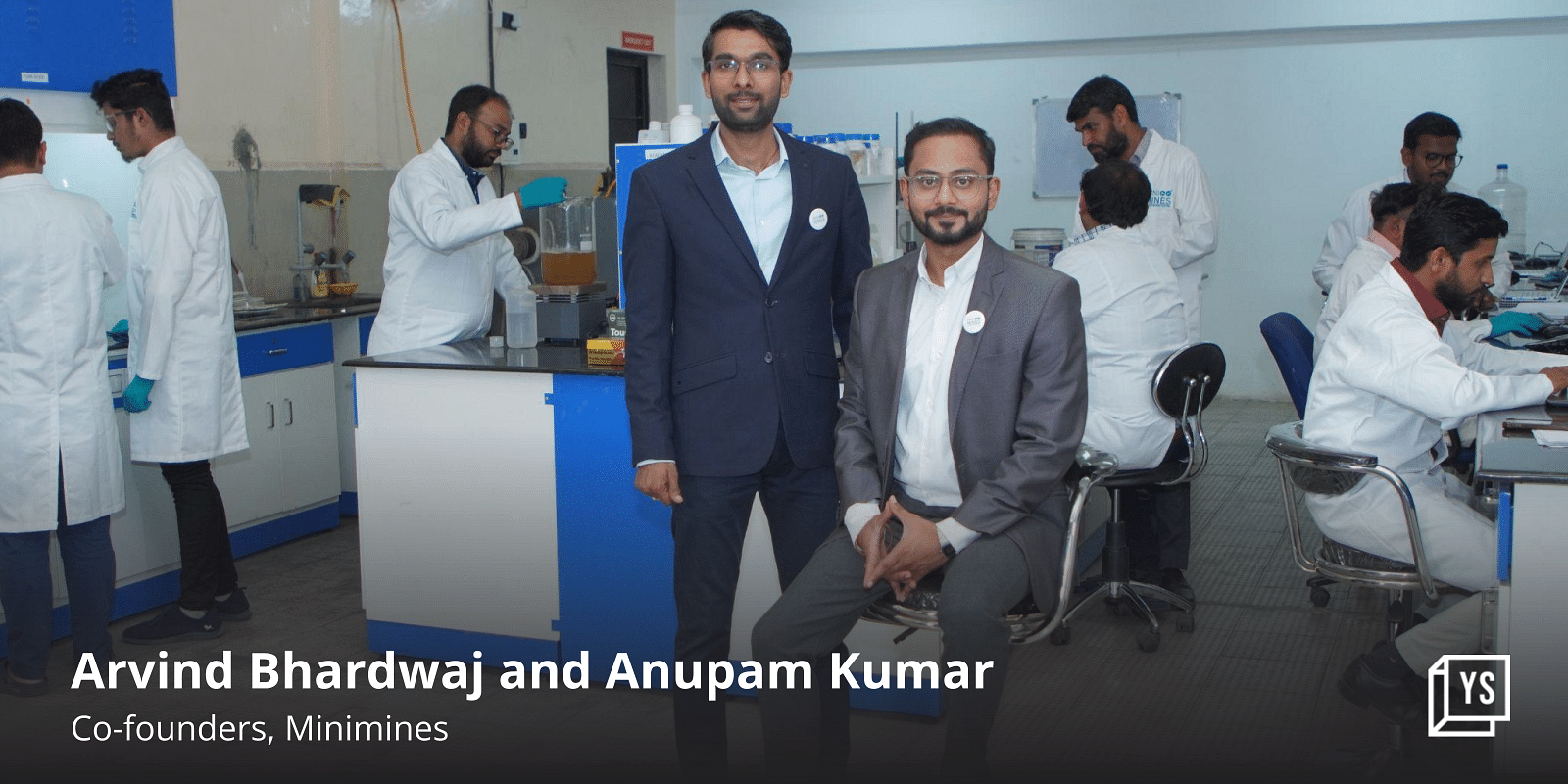

Founded by Anupam Kumar and Arvind Bhardwaj in 2021, the startup says that its proprietary hybrid-hydrometallurgy process can achieve a purity level of nearly 96%, and extract elements such as lithium and precious metals in their elemental states.

Importantly, the process does not produce any water, residual, or carbon dioxide waste or emissions, ensuring the entire process remains environment-friendly.

“India generates nearly 70,000 tonnes of lithium-ion waste annually…from cell phones to laptop and wireless headphones, Li-ion batteries are present everywhere, in most modern gadgets we discard. And while we invest a premium in importing lithium cells for our electric vehicles, a significant amount of valuable and recyclable lithium-ion waste is unfortunately discarded in landfills or incinerated,” Kumar tells YourStory in an interview.

<figure class="image embed" contenteditable="false" data-id="524022" data-url="https://images.yourstory.com/cs/2/f49f80307d7911eaa66f3b309d9a28f5/2022-featuredimages23-1692708589895.png" data-alt="Minimines" data-caption="

Scientists at Minimines

” align=”center”> Scientists at Minimines

.thumbnailWrapper

width:6.62rem !important;

.alsoReadTitleImage

min-width: 81px !important;

min-height: 81px !important;

.alsoReadMainTitleText

font-size: 14px !important;

line-height: 20px !important;

.alsoReadHeadText

font-size: 24px !important;

line-height: 20px !important;

“Our thinking was that if we’re able to take all of this waste lithium ion and other precious metals, and recycle them, we could not only help make India more self-reliant but also bring down the cost associated with cells and batteries used in electric vehicles,” he adds.

Minimines’ proprietary extraction technology has been validated by the NITI Aayog. Its pilot scale unit was audited and certified by Oil India Ltd, which awarded it a grant of $500,000, and The United Nations Industrial Development Organization (UNIDO).

How it works

Minimines’ hybrid hydrometallurgy uses three key processes to create 96% pure elemental lithium and other metals:

- Extraction: Metal or components that contain the metal parts from a battery or a cell phone are extracted and readied for the next step.

- Separation: This process involves the separation and extraction of lithium, nickel, cobalt, and manganese through the principle of varying solubility of metal salts at different temperatures, pressures, and pH levels. The solvent used here is water, which is reused every time the process is repeated, therefore reducing effluent waste.

- Beneficiation: A process that encompasses a range of purification processes such as crushing, grinding, screening, washing, flotation, and other methods designed to concentrate valuable elements.

“There’s no liquid or solid waste or discharge during or at the end of the process. The solvent we use is water, which we reuse,” says Kumar.

After the extraction, these metals are sold not just to EV battery makers, but also find applications in sectors such as grease production, pharmaceuticals, catalyst manufacturing, and the metallurgical industry.

Grants from Oil India Ltd, the Indian government’s Biotechnology Industry Research Assistance Council (BIRAC), and others have helped Minimines scale from its pilot unit to a commercial scale unit, the company says. It next wants to raise funding to set up a full-scale facility.

<figure class="image embed" contenteditable="false" data-id="524024" data-url="https://images.yourstory.com/cs/2/f49f80307d7911eaa66f3b309d9a28f5/2022-featuredimages24-1692708720517.png" data-alt="Minimines" data-caption="

Engineers at Minimines

” align=”center”> Engineers at Minimines

.thumbnailWrapper

width:6.62rem !important;

.alsoReadTitleImage

min-width: 81px !important;

min-height: 81px !important;

.alsoReadMainTitleText

font-size: 14px !important;

line-height: 20px !important;

.alsoReadHeadText

font-size: 24px !important;

line-height: 20px !important;

Revenue model

Minimines, which counts , , and as its competitors, has identified several revenue streams for its business:

- Commodity sales, which is its biggest revenue generator, and refers to the sale of elements it recovers during its extraction process.

- Licensing/royalty which involves licensing its proprietary technology to different geographic regions and companies so they can set up their own extraction plants.

- Sales of carbon credits: because Minimines’ hybrid-hydrometallurgy is a non-polluting process, it receives Certified Emission Reduction (CER) units, which it can then sell to other industrial bodies.

Kumar says that for every $4,000 it spends on the extraction of precious metals, it recovers $8,820 worth of metals.

The startup hopes to partner with manufacturers and producers to help them fulfill their battery Extended Producer Responsibility (EPR), which involves taking on the responsibility for the entire lifecycle of their products, including their proper disposal and recycling once they reach the end of their usefulness.

It is estimated that by 2031, the lithium-ion battery market will be valued at $135.1 billion, growing at a compound annual growth rate of 13.1% from 2023 when it was valued at $48.6 billion, as per MarketsAndMarkets.

Lithium-ion batteries will become important not just in the context of EVs, but also energy storage, as the world moves towards more sustainable means of electricity generation and distribution.

Edited by Affirunisa Kankudti