As a business owner, you know that any kind of downtime means a loss of revenue. And prolonged loss means cuts. So here are some ways to ensure continued production.

Precision Engineered Parts

Any machinery, devices, or mechanisms you might need can make your business dependent on them. As a result, continued supply is necessary. For instance, as a vehicle customization garage, you might need continuous access to nuts, bolts, and exhaust parts. Some of which you cannot simply buy from a DIY store. Fortunately, specialist precision CNC machining companies like Advance CNC can use their technologies. They can design and manufacture highly complex and accurate metal parts for almost everything you could possibly imagine.

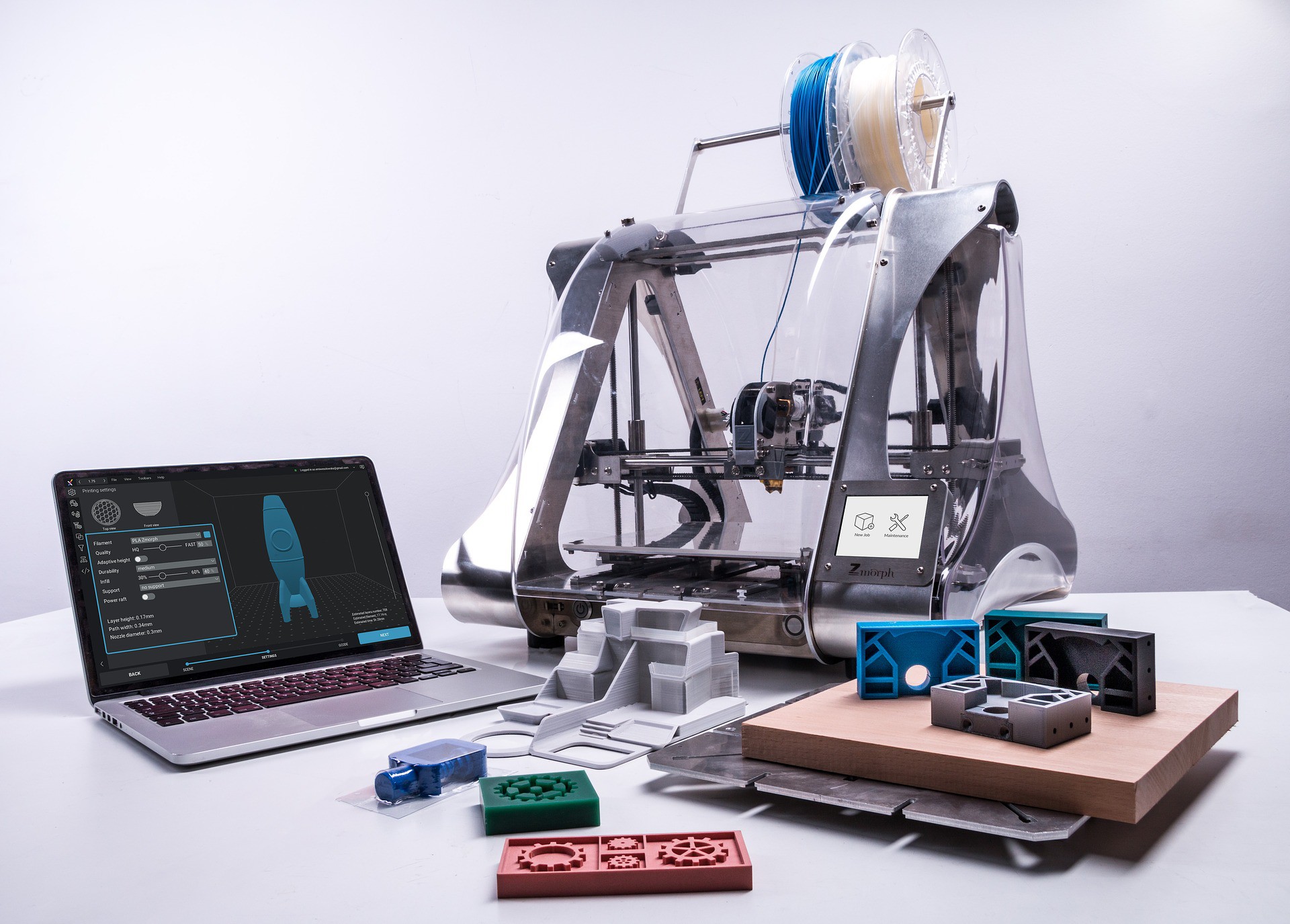

3D Printing Technology

Like metal parts, plastic parts can become worn, or you might need precision parts for a client project. 3D printing technology can be a godsend for simple fabrication. And while 3D printing was once an in-joke in industry, it has come a long way in recent years. It might not be as accurate as a CNC device. But a modern and good-quality 3D printer is more than capable of fabricating small or large parts that aren’t too intricate. So, you can develop all the parts you need in case of supply shortages (such as the one right now) or temporary unavailability.

Ensure Continued Production By Investing in Automation

In modern industry, around 26% of an employee’s work day is wasted by unnecessary tasks that could be done by technology. For almost every industry, automation plays a major role in increasing productivity and production in general. With automation, you can release your staff from menial and boring work prone to mistakes by letting a computer do it better. Common automation investments you can make include scanning data rather than human data entry, automatic stock reordering, and repetitive precision work like applying paint to parts.

PLCs and Controlled Area Networks

PLCs and CANs aren’t anything new. But the advancements in their technology and uses for them have improved. For example, you can connect PLCs across a CAN to report precision data and automatically control an environment. This is a considerable advantage in manufacturing specific products. One example would be pharmaceutical tablets for a client. You can manage multiple tablet press machines using PLCs over a CAN and adjust all output levels in real-time from a remote interface. This also helps where it might be dangerous for employees.

Don’t Forget About the Cloud

Of course, the Cloud is an excellent tool for staying productive. The past few years have made that abundantly clear. Millions of people had to work from home because of COVID-19, so cloud-based systems were a massive help for staying in business. You can liaise with clients over a vast distance using real-time video apps. And your team can continue collaborating on projects remotely when meeting in person isn’t possible. Additionally, you can use multiple apps for managing employee schedules and keeping track of stock for your business.

Summary

There are circumstances in which you need to ensure continued production. Some of the best tech for this includes CNC engineering, process automation, and cloud-based software.

![Read more about the article [Funding roundup] PropReturns, Attentive, Ganit, ConsCent, BosonQ raise deals](https://blog.digitalsevaa.com/wp-content/uploads/2022/07/PROPGAP-1657616800251-300x150.jpg)