As the world works towards the Net Zero Emissions by 2050 Scenario — detailed by the United Nations here — to combat climate change, the rise of sustainable energy alternatives has been a driving force in helping countries reach that goal.

However, a major factor that stands in the way of hitting global Net Zero Emissions is having to radically overhaul the world’s energy storage systems, with today’s installed grid-scale battery storage capacity needing to expand 44-fold to 680 GW by 2030, growing at over 80 GW per year according to this International Energy Agency report.

Rajasthan-based Cancrie has been innovating in this space since 2020, and has not only developed nanomaterials that can be used in batteries and capacitors to increase their efficiency by up to 125 percent, but also does it using agricultural waste. Their patented product uses a proprietary manufacturing process that uses 75 percent less energy, and reduces greenhouse gas emissions by 13 times.

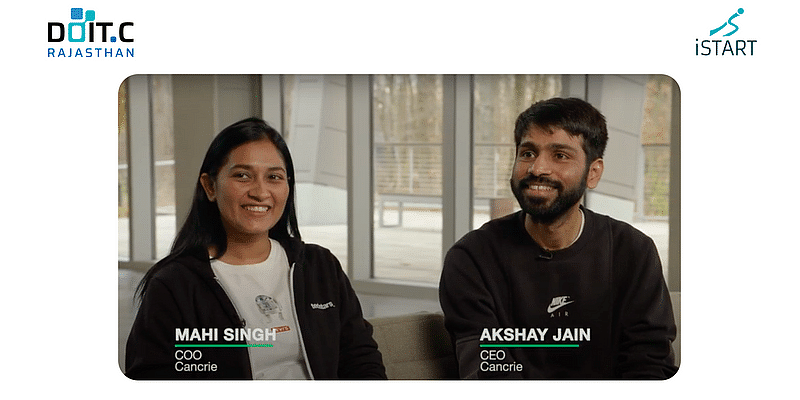

Co-founders Mahi Singh and Dr Akshay Jain, who are Cancrie’s COO and CEO, respectively, explain that their product aims to solve two issues. “Firstly, it is an advanced material that increases the performance in batteries and capacitors. With the inclusion of Cancrie’s material, we’re making batteries more efficient — that means lesser mining, fewer emissions in the entire battery production cycle, and saving costs for the end user. Secondly, we use waste as the raw material sourced from small-scale and marginal farmers, which adds a secondary source of income for them,” Mahi says.

Developed by Akshay, who has a PhD in Chemical and Biomolecular Engineering from the National University of Singapore, over 10 years of experience in waste upcycling and nanomaterials, and secured two patents by himself, the nanomaterial is based on cutting-edge shape technology that has a unique combination of surface area, pore network, surface wettability, and functionalities, that enhances the electrochemical reactions on electrode plates at a molecular level. He also developed the novel proprietary process to consistently produce high quality, battery grade materials, through energy efficient processes and circular manufacturing. This reduces the burden on the supply chain and helps Cancrie provide its premium quality material at an economical price.

“Cancrie has developed and tested these batteries at an industrial scale in third party accredited laboratories. The results we have gotten are exemplary which has caused leading battery manufacturers to have an interest in their product. We are increasing the energy efficiency of the batteries by 40 percent, increasing the lifecycle by at least 25 percent, and increasing the energy density by 20 percent. For the end users, it means that an e-rickshaw driver can earn extra revenue, inverter batteries will give extra backup time, and solar farm lifetime cost savings will be brought down to approximately 20 percent,” shares Mahi, who studied in Nanyang Technological University, Singapore and worked in strategy and marketing roles before coming back to India to start her own company.

Both Mahi and Akshay have previously worked for climate change solutions, with Mahi also working as a climate coach with teams that have worked on reducing CO2 emissions in real time in India, Thailand, and Kenya, and securing a scholarship membership at Women in Cleantech and Sustainability. In addition to his two patents, Akshay has 15 peer-reviewed publications and 10 international conference presentations based on carbons and its application in Energy Storage and Water treatment, and is also associated with the United Nations Environment Programme.

“One thing we have realised is that patience is the key to achieving a bigger vision by taking small steps. Even though we are a startup, we have always considered ourselves as a company and are here to stay for the long term,” Mahi says, adding that Cancrie is working on a paid pilot with the United Nations Industrial Development Organization, to make high performing energy storage devices using their advanced nanotechnology. “We started making our product in the labs at a scale of one gram per day. Today, we have a pilot scale setup at Rajasthan State Industrial Development and Investment Corporation (RIICO) in Jaipur where we can produce 2,000 grams a day of the product with consistent quality and make high performance batteries with it,” she adds.

Setting up in Jaipur, Cancrie has also been recognised as a promising startup by the state government’s flagship startup program iStart Rajasthan, which has helped the company find funding through direct grant investments and by connecting them with investors.

“iStart is a great platform for us as being in the hardtech space we need a lot of support both financially as well as networking. It’s wonderful to see that Jaipur has come up as a fast growing startup ecosystem in India, big credit goes to the fast process and great support that iStart is giving us. We’ve also heard people say that it’s interesting to see a hardcore materials company emerging from Jaipur. iStart recognizes this and gives us all the support and encouragement we need, also through events such as the Jodhpur DigiFest 2022, which was our first time showcasing our technology. It was so motivating to see people across different sections and age groups feeling proud to see a product like ours. We also had the opportunity to present our technology to Rajasthan Chief Minister Ashok Gehlot,” Akshay adds.

Now in advanced talks for market deployment of their product, Cancrie has also expanded their team with Amitej Rao working as Head of Product Development and even has Rajarshi Sen, former CEO of leading Indian battery manufacturer Luminous, as an advisor. The company is now focusing on scaling their product and customer portfolio, as well as work on fine tuning their other offerings.

“We are working with a leading battery manufacturer in India where their material is in beta phase, and will start selling our product soon to another customer in a smaller batch through a pilot scale plant in RIICO, Jaipur. We also plan to set up our full-scale commercial plant in 2024, and have a pipeline of customers in India and in the US. We also have minimum viable products in lithium-ion, sodium-ion, and vanadium redox flow batteries and have developed high performing lithium-based technology with promising results — this work was done in collaboration with a leading research institute in India,” Akshay concludes.